À Propos des Produits PSE

Qu’est-ce Que l’PSE? Qu’est-ce Que la Mousse PSE?

Teknopor EPS “expanded polystyrene foam” is an economic and lightweight thermal insulation material derived from petroleum in the form of foam, generally white thermoplastic consisting of 98% air and 2% plastic with closed porous structure.

Small polystyrene granules are heated with water vapor and expanded by inflating with pentane gas, an organic component. The pentane gas in numerous small closed pores, which form in the granules, is replaced by air during production and within a short time after production. After dried in special silos and inflated with water vapor again, the granules stick firmly to one another without any gaps and take the shape of the mold they are in, resembling honey combs; thus, EPS thermal insulation blocks known as EPS foam or EPS Styrofoam are formed.

This motionless and dry air, which is trapped in the granules with small closed pores, enables EPS thermal insulation to provide superior thermal insulation for buildings. Dry and motionless air within numerous granules constituting EPS does not create thermal bridges, and ensures excellent thermal insulation by preventing heat loss.

Produits PSE de Teknopor

Teknopor is the brand for EPS products of Teknopanel. Graphite Teknopor is the brand of EPS thermal insulation boards produced with the addition of grey graphite. Graphite Teknopor gains infrared absorption and reflectivity features with its graphite addition, and increases thermal insulation performance by reducing the material’s thermal conductivity value.

Teknopor EPS products are used in various parts of the buildings from basis to roof and from wall to floor. Alongside Teknopor and Graphite Teknopor Thermal Insulation Boards, the products manufactured under the brand of Teknopor are Teknopor Perforated Thermal Insulation Board, the light filler material used in building concrete floor Teknopor Light Filler Blocks, Teknopor Geotek Subsurface Filler Blocks used in the construction of highways and bridges, and EPS Jamb Block used as exterior trimming material.

Propriétés Techniques de la Mousse PSE

Having a durable and robust structure, EPS products are among the most practical and economic materials when applied in accordance with the standards and in correct thickness and density according to their usage area and the climate of the region.

The fact that EPS products can be manufactured in various densities facilitates to present products with the desired technical values. The motionless air in small closed pores which constitute EPS product ensures low thermal conductivity and high thermal insulation values. It is also dampproof, steam-tight, and repels water.

Environment-friendly EPS products are flexible and have a durable structure against temperature changes and time. Therefore, they do not show dimensional changes such as extension or shortening. They are also quite resistant against mechanical factors. Thanks to their lightness, they do not put extra load on the structure they are used in.

As an end product, EPS has features such as lightness, free-machining and usability in the manufacturing of other composite products together with other materials.

Production de PSE

We fabricate all products under the roof of Teknopanel in our indoor area of 46.000 m2 in total in Mersin, Sakarya, Izmir and Istanbul. We are the most important producer of the sector with our 460 employees and an annual total production of 1.6 million m3 of EPS on 6 production lines at our facilities of advanced technology.

We use clean technology by turning towards clean and renewable energy resources in our EPS production facilities within the scope of our environmental protection policy. No solid waste is generated at the end of EPS production by using minimized water and energy consumption within a closed circuit. As the waste generated during cutting process is recyclable, it is integrated into production again immediately or afterwards. Emissions into underground resources and atmosphere are kept at minimum level and controllable point.

Zones d'Application de la Mousse PSE

EPS products are especially used for thermal insulation in buildings, and are also useful for sound insulation. In addition, they offer solutions for different purposes in special engineering constructions and sectors other than construction. Usage areas of EPS get diversified and improved day by day.

Use Of EPS Products For Other Purposes In Buildings

● Expansion joints

● Manufacturing lightweight building blocks (lightweight brick, briquette etc.)

● Manufacturing filler blocks

● Thermal insulation of window shade frames

● Manufacturing lightweight concrete and insulation plaster from EPS granules

● As filling material in door production

● Manufacturing prefabricated lightweight concrete elements

● Insulation of tanks and storages

● Manufacturing composite (multi-layered finished) boards

Use Of EPS Products In Special Engineering Constructions

● Manufacturing floating piers (pontoon)

● Construction of highways in cold regions

● For increasing ground strength by filling in loose grounds

● Expansion joints of bridges

Use Of EPS Products In Other Fields

● Packaging industry

● Manufacturing lifejackets and life buoys for ships

● Manufacturing windsurfing boards

● Manufacturing small boats

● In decoration works

Use Of EPS Products For Thermal Insulation In Buildings

● Thermal insulation of walls in buildings

● Thermal insulation of inclined and terrace roofs in buildings

● Thermal insulation of flooring in buildings

● Thermal insulation of ceilings in buildings

● Thermal insulation of protrusions in buildings

● Impact sound insulation in floating floor applications in buildings

● Formation of multi-layered elements for air sound insulation in buildings (after going through special processes)

● Thermal insulation of cold storages

● Thermal insulation of pipes

● Thermal insulation of poultry houses

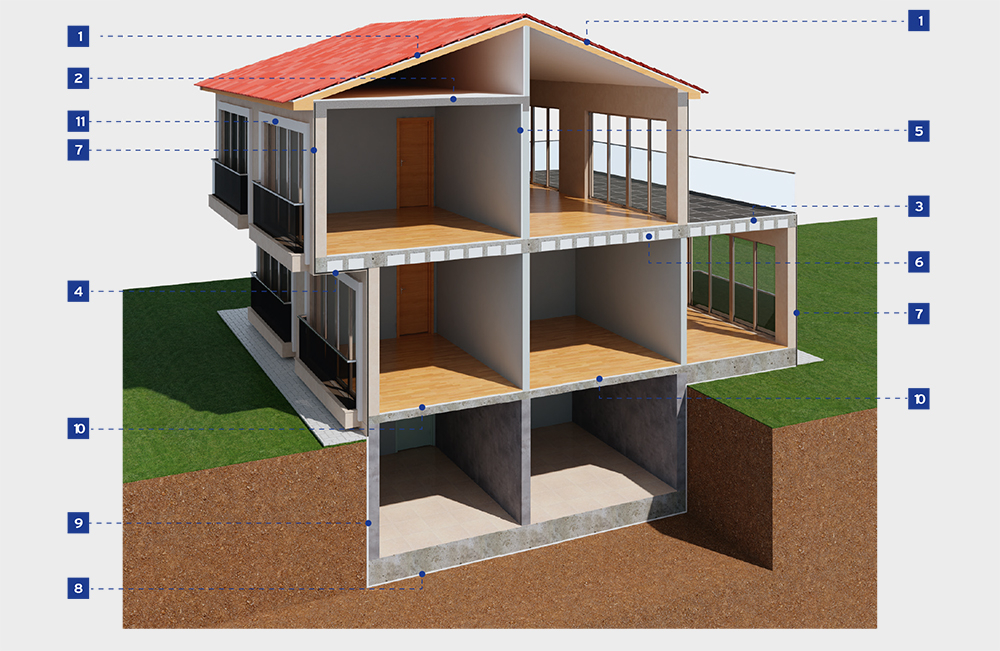

- 1. Thermal Insulation of Pitched Roofings

- 2. Thermal Insulation of Garrets

- 3. Thermal Insulation of Terrace Roofs

- 4. Thermal Insulation of Concoles

- 5. Thermal Insulation of Interior Walls

- 6. Light Filler Block of Floors

- 7. Exterior Wall Thermal Insulation

- 8. Thermal Insulation of Underfloor Layer for Basements

- 9. Thermal Insulation of Basement Shear Wall

- 10. Thermal Insulation of Floors

- 11. Exterior Wall Jambs

Advantages de PSE

- Low thermal conductivity value provides high thermal insulation.

The lower EPS thermal insulation boards’ thermal conductivity value is, the more thermal insulation they provide. Thermal conductivity value of EPS boards reduces as their the density and thickness increase. As the pentane gas within EPS thermal insulation boards is replaced by dry and motionless air, its thickness does not change significantly when used under load for a long time. It preserves its low thermal conductivity value, and continues to provide ecellent thermal conductivity.

- It has high mechanical compressive strength.

When preferred with the correct thickness and density according to its usage area, EPS thermal insulation board show a superior mechanical strength against long-term loading and impacts, and does not lose its thermal insulation value.

- It repels water, prevents humidity and bacterial growth.

Granules of EPS thermal insulation boards sticking firmly to one another and having close pore structure ensures that the board has a very low water absorption rate when it contacts with water. Thanks to its water-repellent structure, none of its features change even though it contacts with water.Close porous structure is resistant against condensation in the air, and does not allow transmission of humid air. It prevents humidity and moisture, as well as the corrosion of load-bearing system accessories. Moreover, it prevents humidity, microorganism growth and mold in interior environments. Therefore, it protects human health.

- It has high dimensional stability.

Thermal insulation materials should have high dimensional stability. Dimensional change in buildings may occur due to thermal expansion in consequence of the effect of different temperatures, as well as independently of external factors within a certain period of time after production. Dimensional stability should be considered separately according to temperature and time.The dimensions of EPS thermal insulation materials at the time of application are not deformed due to thermal and mechanical effects within time. Having a high dimensional stability, EPS is an ideal material thanks to its resistance against seasonal changes. This provides an important advantage for civil engineering applications.With its high compressive strength, EPS offers features that do not change according to load and time for floors, traffic areas, classroom and lecture hall floors and road embankments.

- Its lightness is an advantage.

EPS offers a considerably advantageous weight/volume performance compared to other building materials in construction sector. As its closed porous structure consists of 98% air, it is light, and does not place additional load on buildings. It is easy to load and stack.

- It is an economic solution.

The cost of EPS products for construction sector is lower by approximately 1/3 compared to other alternative products. It provides a minimum cost advantage of 20% compared to mineral wools(rock wool and glass wool). It also comes to the forefront as the most appropriate material in terms of maintenance expenses of existing buildings.The strength of EPS is high although it is a light material. It has low labor cost as it is easy to carry and can be installed quickly. Moreover, it contributes to the reduction of gas emission with low transportation costs and low fuel consumption.

- It is heat and cold resistant.

Thermal insulation materials are expected to show a long-lasting and non-decreasing performance against heat and cold. Maximum resistance of EPS against high temperatures depends on the degree and duration. EPS can be used until 75-85 oC at maximum and -180 oC at minimum according to density and environmental conditions over the long term. This resistance feature increases the number of areas EPS is used.

- It is fireproof.

As per TS EN 13501-1, EPS boards are classified as materials having a minimum fire performance of “E” and consisting of raw materials defined as B1 flame proof. When EPS thermal insulation boards are used as components of exterior thermal insulation systems outside of buildings, they have a fire performance of B. When used coated with materials such as plaster, alum or plasterboard, it is included in the fire performance class of the coating material used on it, because it is not in direct contact with the source of flames.

- It is easily shaped and processed.

EPS thermal insulation boards inflate in the form of granules with the process applied at the final stage of production. The inflated granules take the shape of the mold they are in. EPS board produced as blocks can be easily cut in required shapes after production.

- It provides excellent thermal insulation.

Thanks to the dry and motionless air in its closed pores, EPS provides ecellent thermal insulation. It is applied in zones where thermal bridges may occur, and surround the building in all sides. It plays an important role in reducing the building’s energy consumption by cutting down heating expenses in winter and cooling expenses in summer. Therefore, it does not increase environmental pollution as it uses less fuel.

- It is installed quickly and easily.

EPS application is quick and easy thanks to its flexible and lightweight structure. Therefore, it saves time and keeps labor costs low.

- It has a flexible structure.

Air pockets in EPS’ pores provide cushioning by serving as a buffer. It absorbs the force of impacts or pressure, prevents contracting or stretching in temperature changes, and is not fragile.

Prix de la Mousse PSE Prix

Les prix de PSE (Polystyrène expansé) varient selon le type, les spécifications techniques et les dimensions du produit à utiliser. Les produits d'isolation thermique en PSE sont plus abordables que d'autres matériaux de construction offrant les mêmes performances. Vous pouvez économiser de l'argent en choisissant les produits Teknopor PSE pour vos besoins en mousse d'isolation, polystrène expansé, matériaux d'isolation thermique en PSE, etc. de votre construction.

Lors de la détermination des Prix de PSE, le bon produit PSE (Polystyrène expansé) doit être sélectionné en fonction des caractéristiques de la structure et du but d'utilisation. Lors du calcul des prix de la mousse de polystyrène, le coefficient de transmission de chaleur et les valeurs de densité souhaités sont également très importants en plus des informations sur les dimensions telles que la longueur, la largeur et la hauteur.

- Prix des Blocs de PSE

Le gaz pentane dans les blocs de PSE est remplacé par de l'air en très peu de temps après que les petites particules de polystyrène aient été chauffées à la vapeur d'eau et gonflées avec du gaz pentane et pré-expansées. Les particules, qui reposent dans des silos spéciaux, sont à nouveau gonflées à la vapeur d'eau et les blocs de PSE sont formés en fusionnant les uns avec les autres sans laisser d'espace entre eux, prenant la forme du moule dans lequel il a l'apparence d'un nid d'abeille. Les blocs de PSE ; Ils peuvent être utilisés à diverses fins telles que l'isolation thermique, le remplissage de sol, la décoration extérieure. Le prix du bloc de PSE varie selon le type, la taille et la densité du matériau utilisé.

- Prix des Blocs Creux en PSE

Les produits des blocs creux en PSE sont utilisés comme matériau de remplissage dans les bâtiments. Le PSE, généralement utilisé pour combler les vides dans les bâtiments, n'apporte pas de charge supplémentaire à votre bâtiment car il s'agit d'un matériau de remplissage léger, tout en vous évitant le fer, le béton et les coffrages utilisés dans la construction. Le prix des blocs creux de PSE varie en fonction de la densité du produit, des caractéristiques telles que la largeur, la longueur, l'épaisseur.

- Prix du PSE au Carbone

Les produits de PSE au carbone sont en polystyrène expansé de couleur gris foncé obtenu en ajoutant du graphite lors de la production du PSE. L’addition de graphite dans le contenu des produits en PSE au carbone permet au produit d'acquérir une absorption et une réflectivité infrarouges, diminue la valeur de conductivité thermique du matériau et augmente les performances d'isolation thermique. Ils offrent une isolation thermique plus élevée que les panneaux d'isolation thermique du PSE blancs ou roses.

Les Prix du PSE au carbone varient en fonction du but, de la taille, des dimensions et de la densité souhaitée de la zone à utiliser. Avoir la flexibilité d'être produit avec les caractéristiques demandées n'entraîne pas de gaspillage de matériaux et d'augmentation inutile des coûts.

- Prix des Chambranles en PSE

Utilisé dans la production de jambages, qui sont des matériaux de décoration extérieure.

Les blocs de chambranle en PSE qui sont des matériaux de décoration extérieure sont préférés en raison de leurs caractéristiques telles que la facilité de traitement, la légèreté et l’isolation thermique. Les dimensions des blocs de chambranle sont fixes, mais différentes densités sont disponibles pour les blocs de chambranle. Les Prix des chambranles en PSE varient également en fonction de la densité.

- Prix de Bardage de Façade

L’isolation thermique est assurée en empêchant le transfert thermique entre le milieu extérieur et intérieur sur les bâtiments grâce au bardage de façade. On obtient ainsi plus de 50 % de gain sur le coût et le prix de l'énergie.

Le système de bardage pouvant être commandé en tant que système contient des panneaux d'isolation thermique blancs ou au carbone, de l'adhésif, de l’enduit décoratif et des accessoires de montage.

Le Prix du bardage de façade est calculé en fonction du type de mousse de carbone ou de mousse de polystyrène à sélectionner, du coefficient d'isolation thermique et de la valeur de densité souhaités, des dimensions de la mousse de polystyrène telles que la longueur, la argeur, la hauteur. Le prix du bardage est calculé en mètres carrés.

Vous pouvez nous contacter pour obtenir des informations détaillées sur les prix de PSE, déterminer le produit adapté à vos besoins et obtenir un prix raisonnable.

Pour obtenir des informations sur les prix du polystyrène ou de bardage, le prix de l'isolation thermique extérieure et d'autres produits, appelez-nous sur la ligne de communication +90 0850 777 0850 ou via le Formulaire d'information suivant.